Nearly three years after a liquid nitrogen leak killed six workers at a poultry processing plant in Gainesville, a federal safety board has released its findings into the incident.

This week, the U.S. Chemical Safety and Hazard Investigation Board (CSB) released its final investigation report into the deadly leak at the Foundation Food Group (FFG) facility on January 28, 2021.

The 115-page report identifies a number of equipment and process failures at the facility. It also includes a dozen recommendations to various groups to prevent such tragedies in the future.

Bent tube led to deadly leak

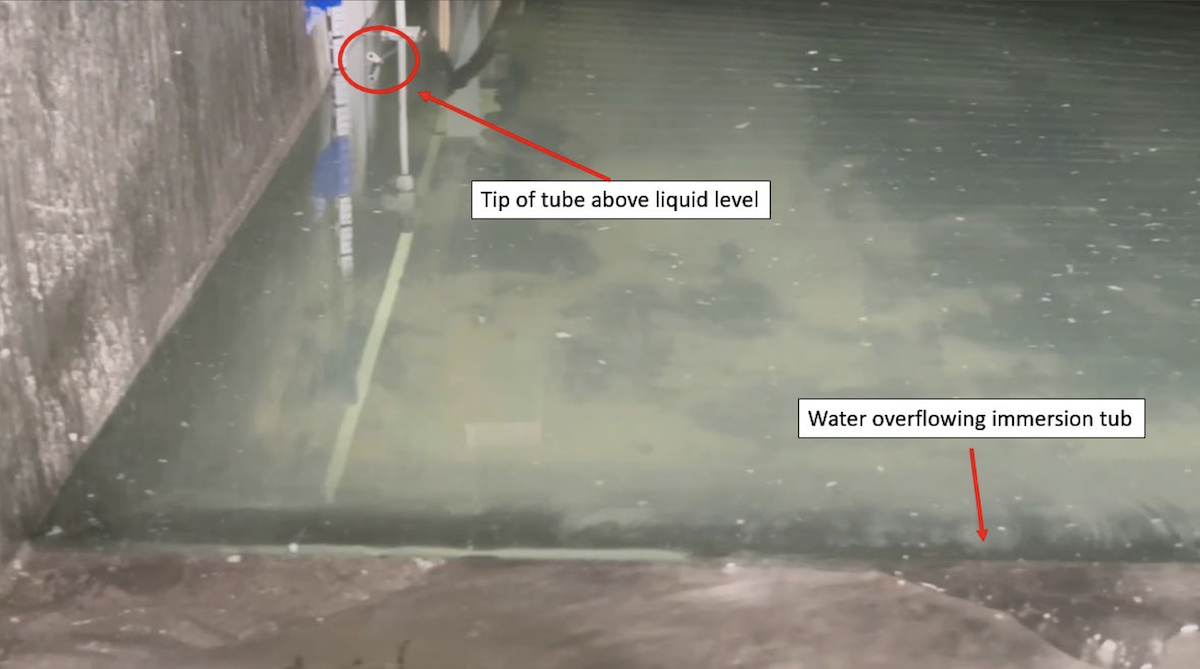

FFG used liquid nitrogen to quickly freeze prepared poultry food products. Investigators determined that a bent “bubbler tube” inside the immersion freezer at the plant caused the leak.

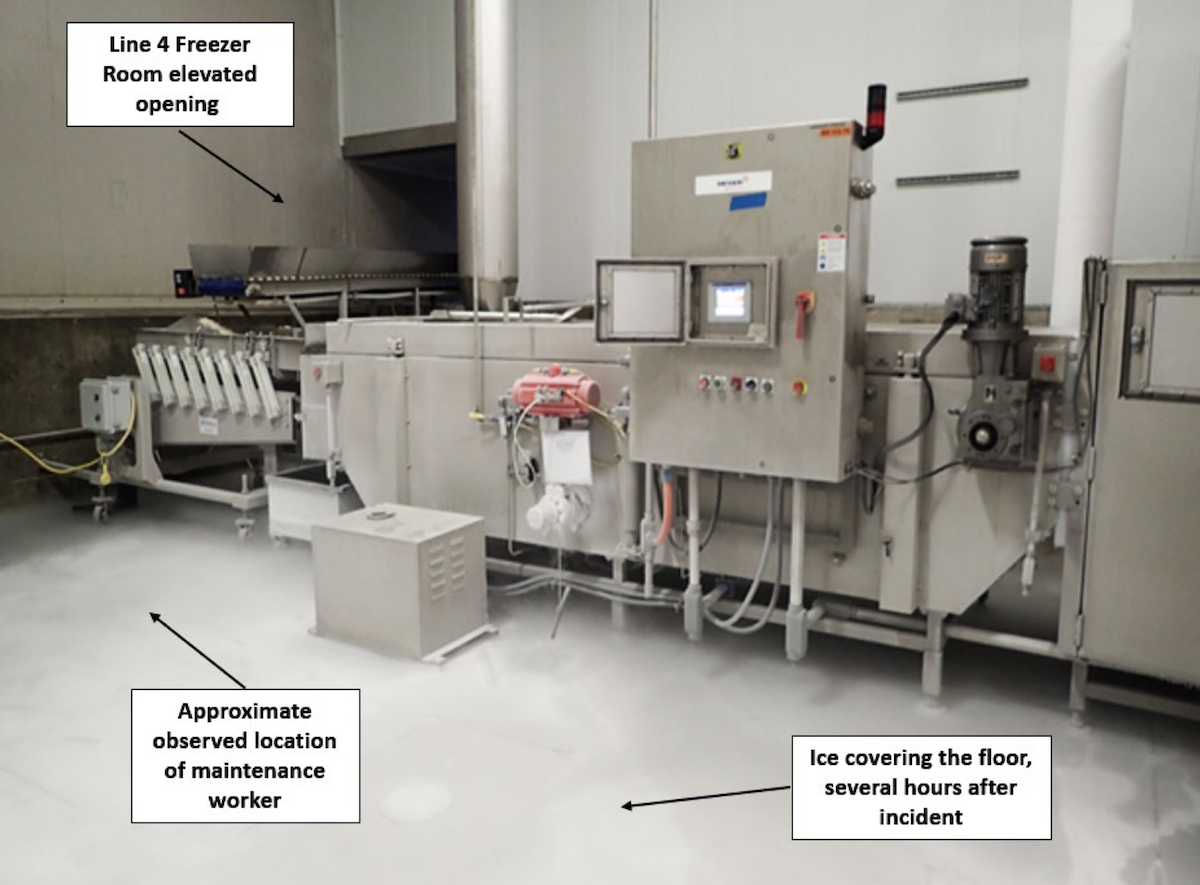

Investigators determined the bubbler tube was likely bent during maintenance, rendering it unable to measure and control the freezer’s liquid nitrogen level. As a result, liquid nitrogen overflowed from the freezer and quickly vaporized into a four- to five-foot-high cloud, causing the employees to die of asphyxiation.

designed, the tube should be pointing straight downward. (Credit: CSB)

Three other FFG employees and a firefighter who responded to the incident were seriously injured from asphyxiation.

Investigators also determined that “inadequate emergency preparedness” made the situation at FFG more severe. According to a summary report of CSB’s findings, FFG did not “inform, train, equip, drill, or otherwise prepare its workforce for a release of liquid nitrogen.”

Investigators also concluded that FFG failed to install air monitoring and alarm devices that could have alerted the workers about the hazardous vapor cloud and warned them against entering the freezer room.

A ‘needless and senseless tragedy’

After the leak, at least 14 employees entered the freezer room and surrounding area to investigate and try to rescue their coworkers.

“Workers were not aware of the deadly consequences of a liquid nitrogen release – ultimately, trying to save their colleagues led to them sacrificing their own lives,” said Investigator-in-Charge Drew Sahli. “This is a known hazard, and better training and communication could have prevented such a tragedy.”

In addition to the lack of training and monitoring devices, CSB found that FFG had no documented process safety management policy. The company allowed the job position responsible for safety management to be vacant for more than a year before the incident.

Messer LLC designed and owned the freezer and leased it to FFG. Investigators noted that, despite Messer being aware of FFG’s “unsafe practices,” the company continued supplying FFG with liquid nitrogen.

“This needless and senseless tragedy was completely preventable. Six people died and four others were seriously injured because of a bent tube and FFG’s failure to have critical monitoring equipment and warning alarms and FFG’s failure to adequately train and equip its employees to respond safely to a liquid nitrogen release,” said CSB Chairperson Steve Owens.

County Fire Services, annotations by CSB)

Safety recommendations

After the incident, FFG sold the facility to Gold Creek Foods. According to CSB, Gold Creek does not have liquid nitrogen freezing processes in the building where the incident occurred.

As a result of its investigation, CSB issued twelve safety recommendations directed at Gold Creek, Messer, the Occupational Safety and Health Administration (OSHA), an industry trade association, and two standard-setting organizations.

The CSB is calling on Gold Creek Foods to “proactively engage” with local emergency responders to ensure that they are aware of the chemicals being stored onsite at the facility and their potential hazards.

CSB also wants OSHA to issue a national standard to address the hazards of cryogenic asphyxiants – which include liquid nitrogen.

Other recommendations include:

- OSHA to cover liquid nitrogen in the agency’s regional emphasis programs for poultry processing and food manufacturing.

- The Compressed Gas Association and National Fire Protection Association to improve their safety guidance on cryogenic asphyxiants.

- International Fire Code updated to require the use of atmospheric monitoring with cryogenic asphyxiants.

“The CSB’s recommendations are important for preventing incidents involving liquid nitrogen and lessening their severity if they do occur,” said Owens. “The hazards of liquid nitrogen must be clearly communicated to workers, and the safety management systems for operations that use liquid nitrogen must be improved.”